Frappe

ERPNext

Industry

Industrial Machinery Manufacturing

industry

Open, Modern, DIY ERP for Industrial Machinery Manufacturers

Say goodbye to your legacy tools with a contemporary manufacturing ERP software that simplifies your industrial machinery business and improves performance.

Start free trial

Best-In-Class Industrial Equipment Software

Whether you’re crafting industrial machinery or high-quality tools, engineering precision is a must for delivering complex and customized products. Meanwhile, machines have gotten faster, more powerful, and more sophisticated. Help your manufacturing processes keep pace.

Get products to market faster while keeping costs down and minimizing liability with ERPNext. It provides not just production planning capabilities but also integrated inventory, document storage, supplier & customer management, and more!

Total control over your production cycle

Keep an eye on your paper business and ensure orders are fulfilled with our Production Analytics Report — an aggregated view of production status. It includes several reports to help you analyze manufacturing load and make insightful decisions.

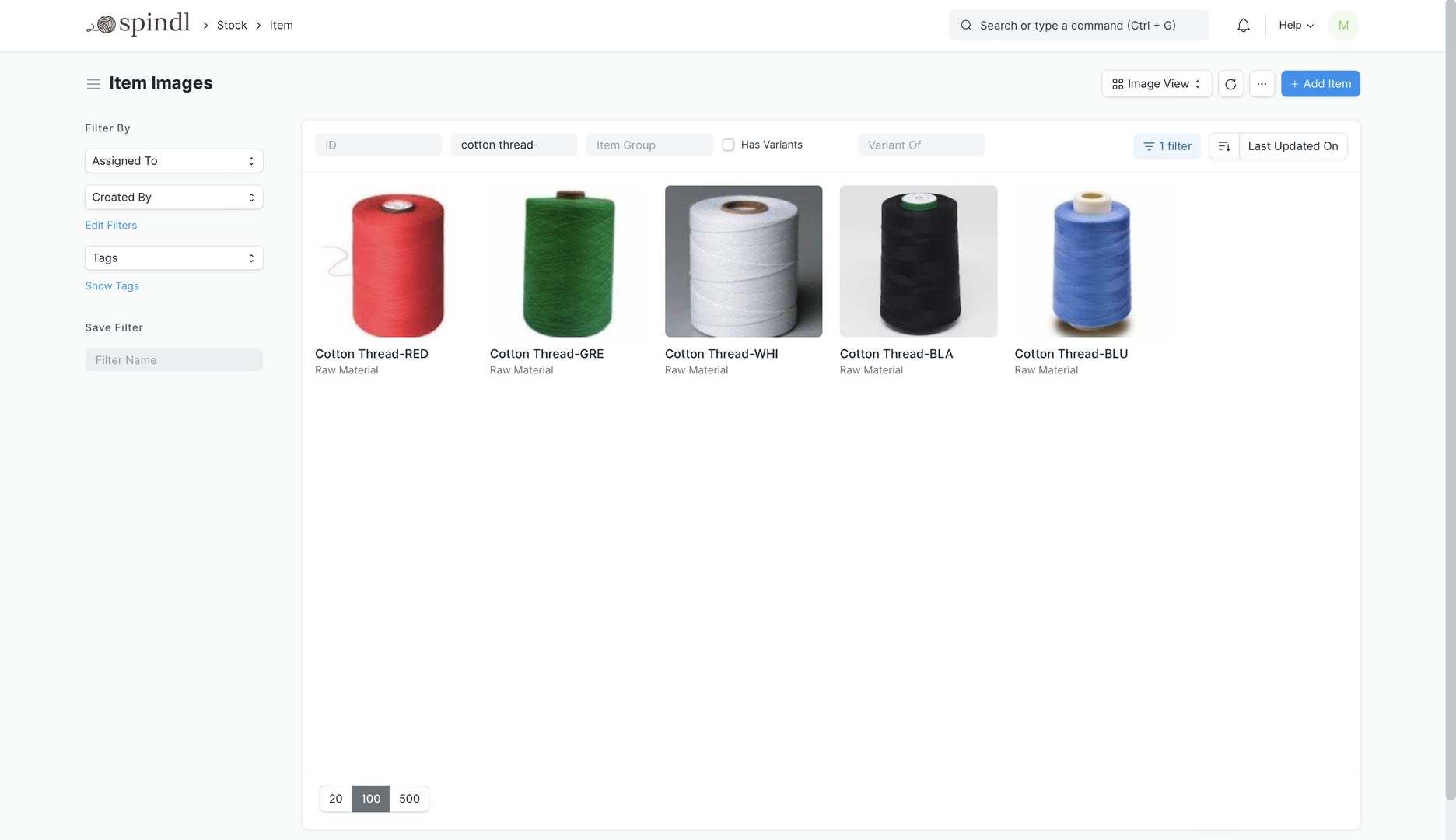

Item Variants

Managing thousands of product permutations, such as voltage or material, is enormously complex. In ERPNext, the primary item is stored as an item template, and each of the variations is stored as an item variant.

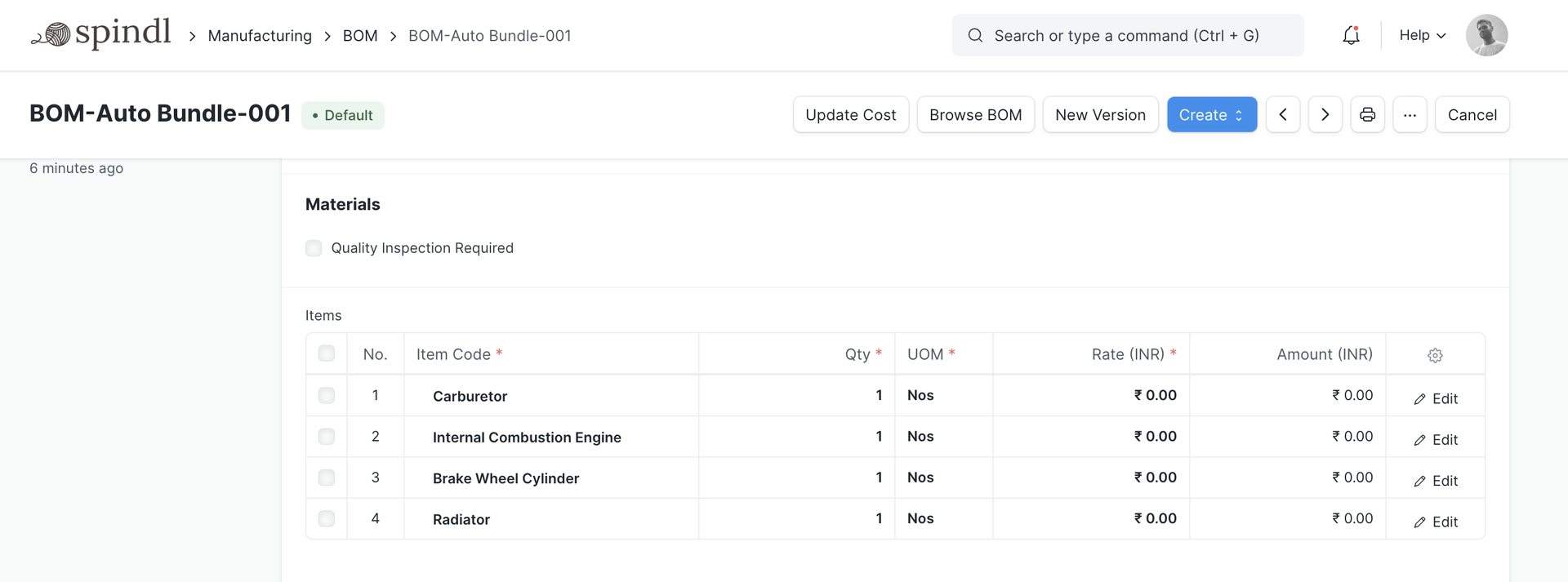

Bill Of Material (BOM)

A Bill of Material is at the heart of any manufacturing ERP software, and a well-defined BOM ensures robustness and accuracy. ERPNext's BOM is hierarchical, with the finished product at the top. It also includes item codes, raw materials, quantities, costs and additional specifications.

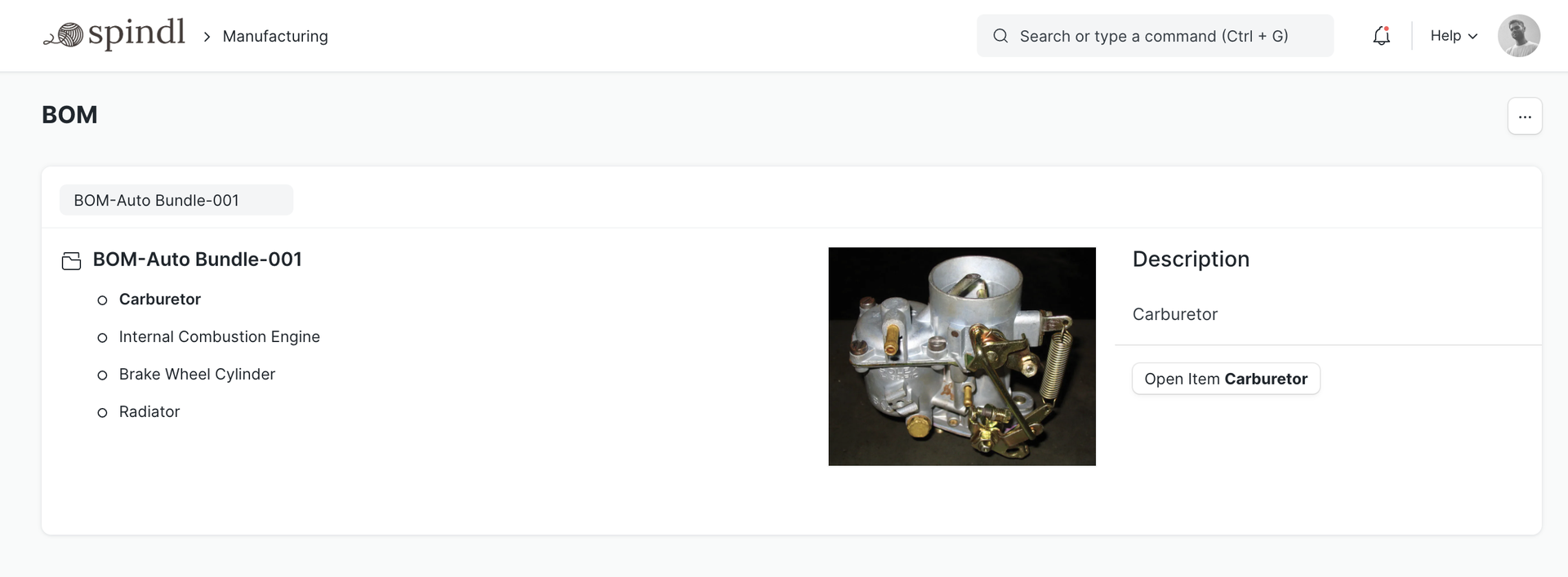

BOM Browser

Navigate through the multiple levels of your BOMs and understand the foundation of your industrial machinery products. With the BOM Browser, you can not only view the BOMs of sub-assemblies, but also update them in real time to maintain accurate costs based on stock value and ongoing procurements.

Shop Floor Management

With the Job Cards, Operations, and Workstations features, you can automatically capture mundane activities on your shop floor. A single screen shows the real-time status of job work, the location of each workstation, employee assignments, and the status and next steps of each work order.

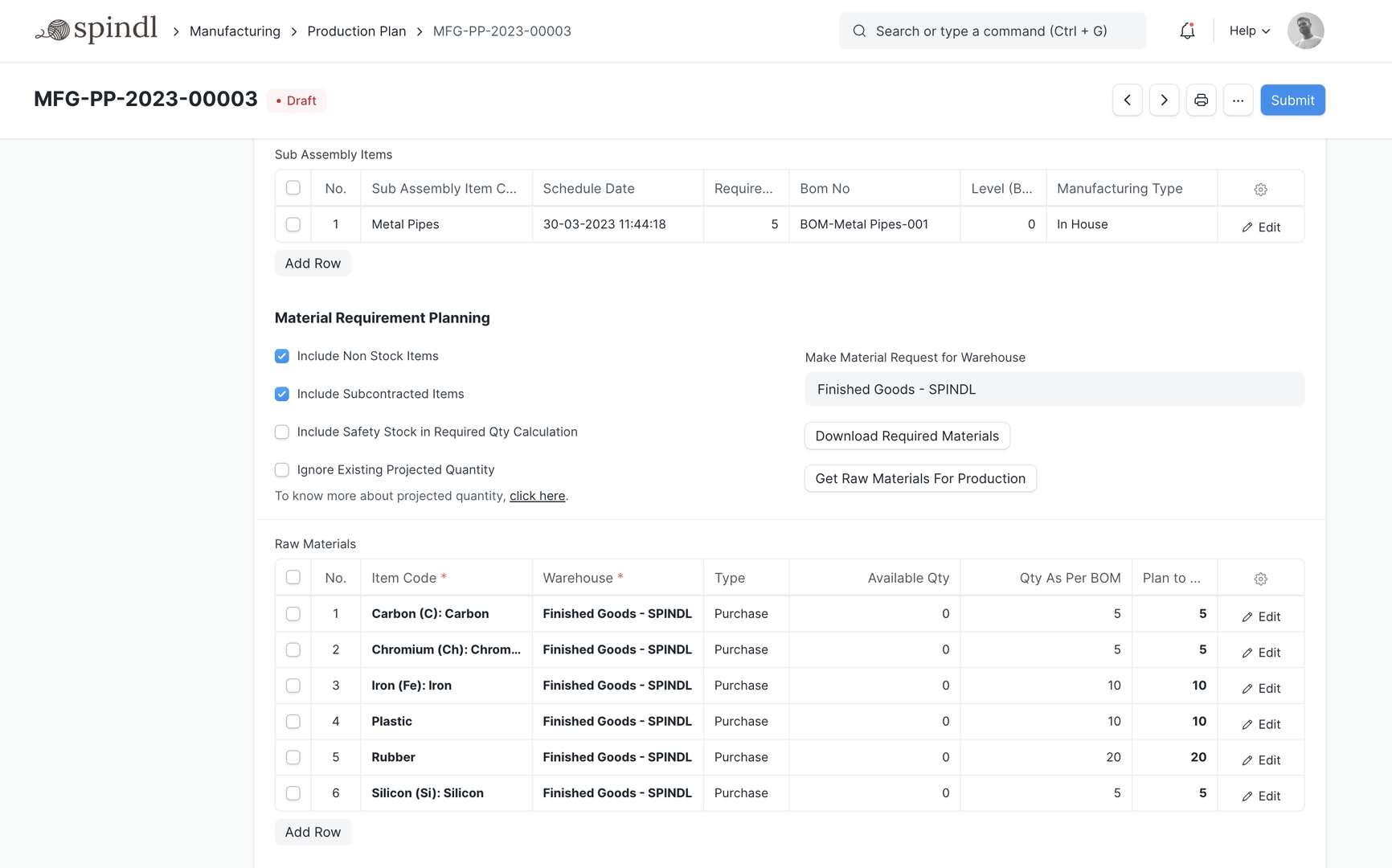

Material Resource Planning

Material procurement and production planning for industrial machinery can become a nightmare. Be it a work order against sales or material requests, ERPNext will show every aspect of your MRP. Track material consumption of batched inventory to curb expenses and achieve zero wasted resources.

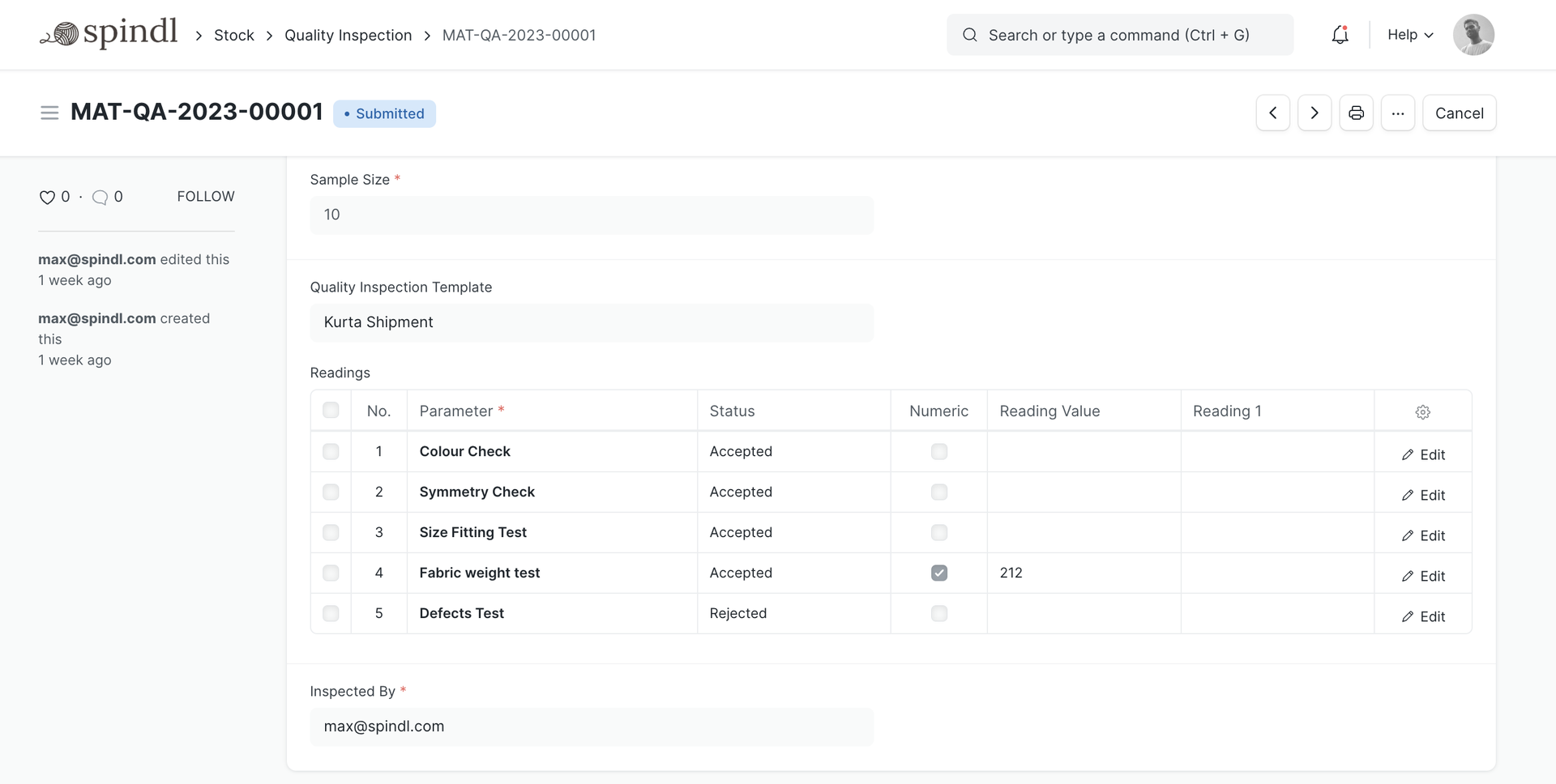

Quality Inspection

Ensure the quality of your incoming and outgoing products with built-in, customizable Quality Inspection Templates. Until inspection is complete, ERPNext will restrict stock from moving. You can also check the quality of the components that are still being manufactured.

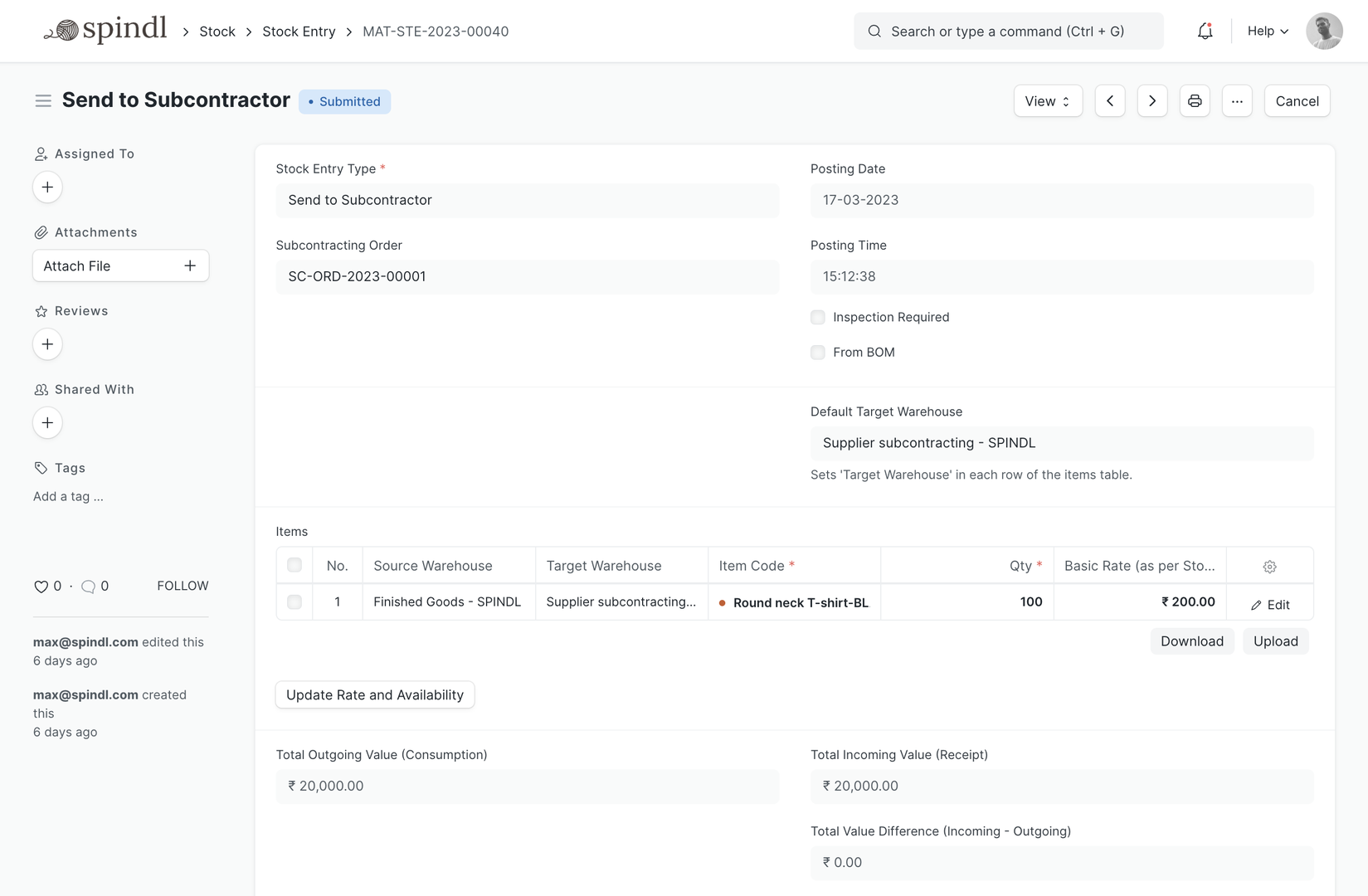

Subcontracting

An industrial machinery business is incomplete without outsourcing. Be it sharpening or engineering sub-assemblies, some jobs have to be outsourced. Use the Subcontracting feature to supply raw materials to a third-party distributor or supplier and easily track all activities.

Capacity Planning

Optimize your workstations based on the resources available for open production orders. Identify and eliminate bottlenecks at the shop-floor level by creating a capacity plan. You can also maintain and manage planning schedules for a predefined period of time (30 days, 45 days, etc).

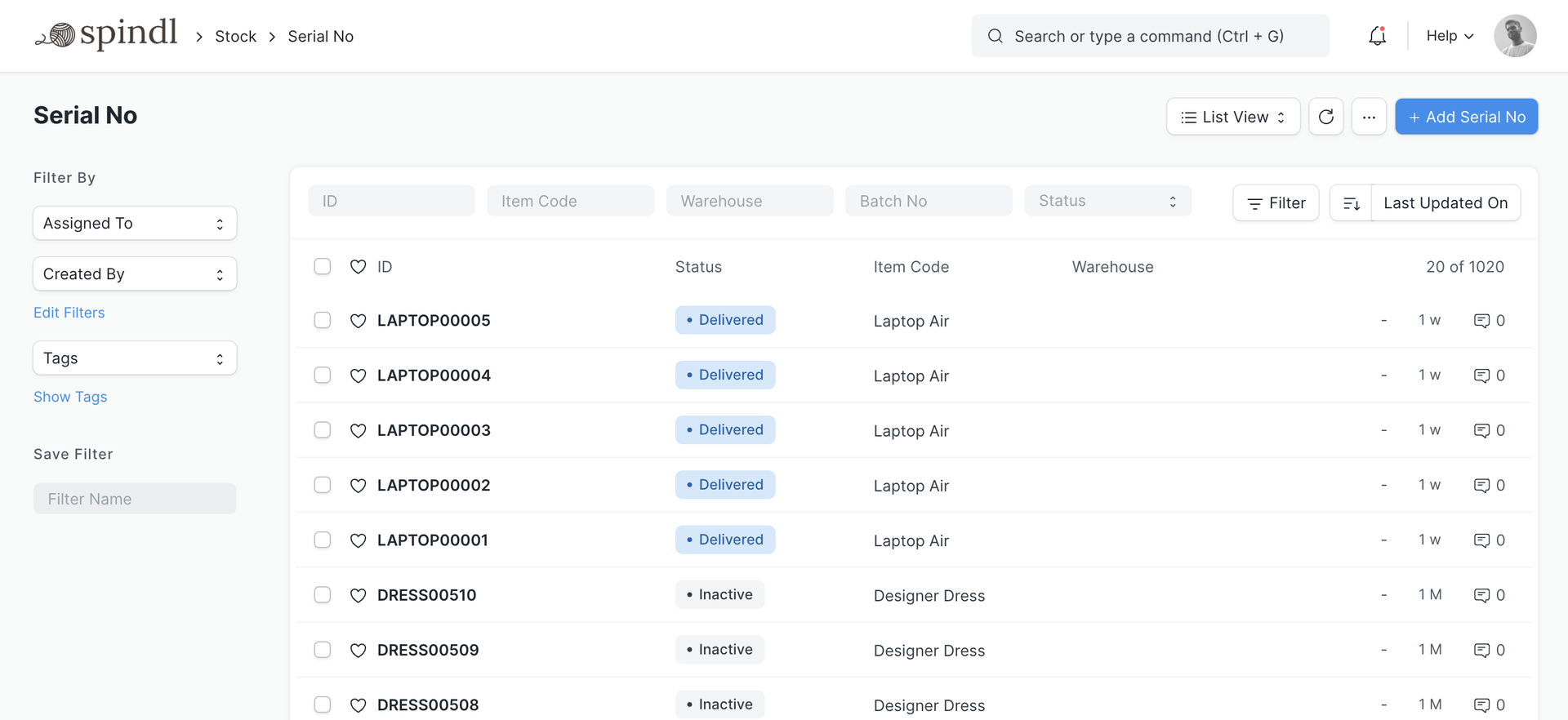

Serialized Inventory

Without a serial number attached to it, any piece of equipment is incomplete. With ERPNext's integrated inventory, you can manage serial numbers, or even automate their creation based on your pre-defined series! You'll get a real-time view of the stock, ongoing transfers, pending receipts, and delivered products. Scan stock using either item barcode or serial number — no obligations.

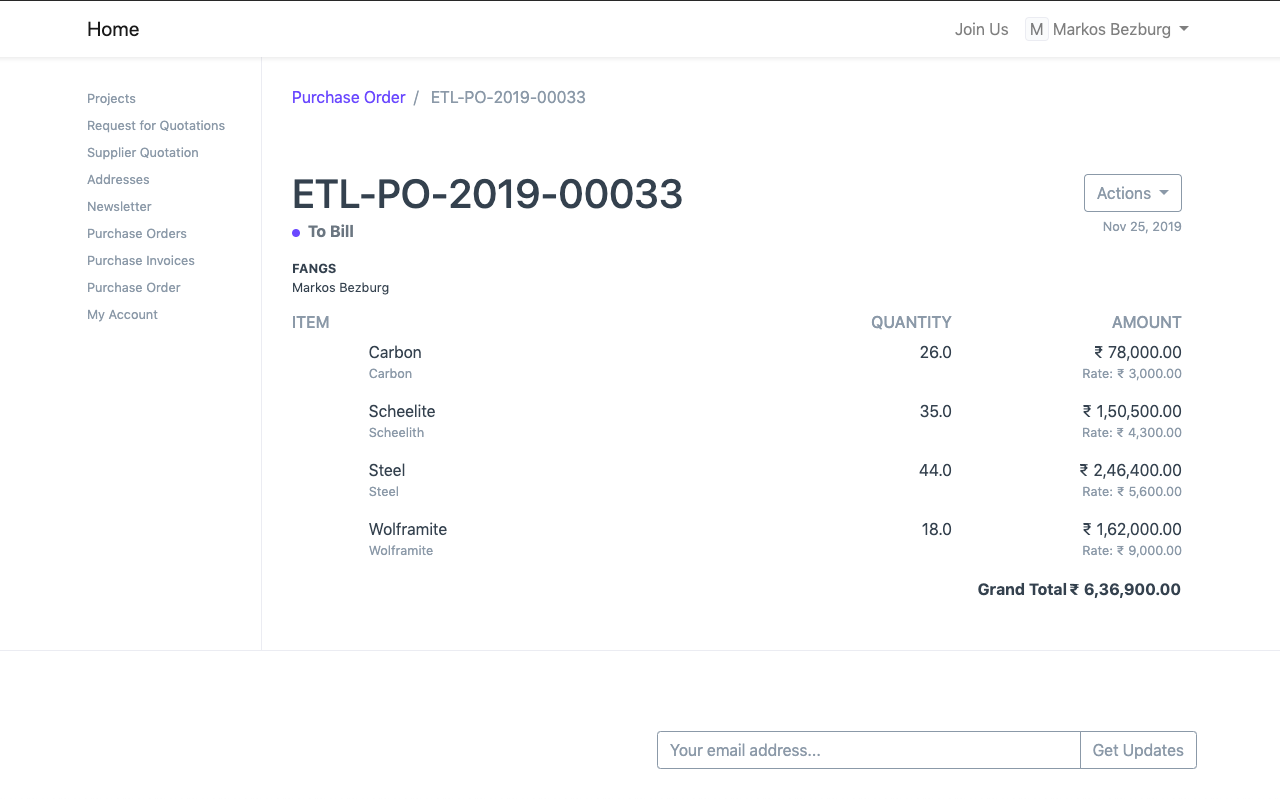

Supplier Portal

Use the supplier portal to help suppliers manage themselves. The suppliers can submit requests for quotations and automatic supplier quotations, or access ongoing purchase orders and receipts. Suppliers can also raise purchase invoices for fulfilled orders. You can then verify these invoices for final approval.

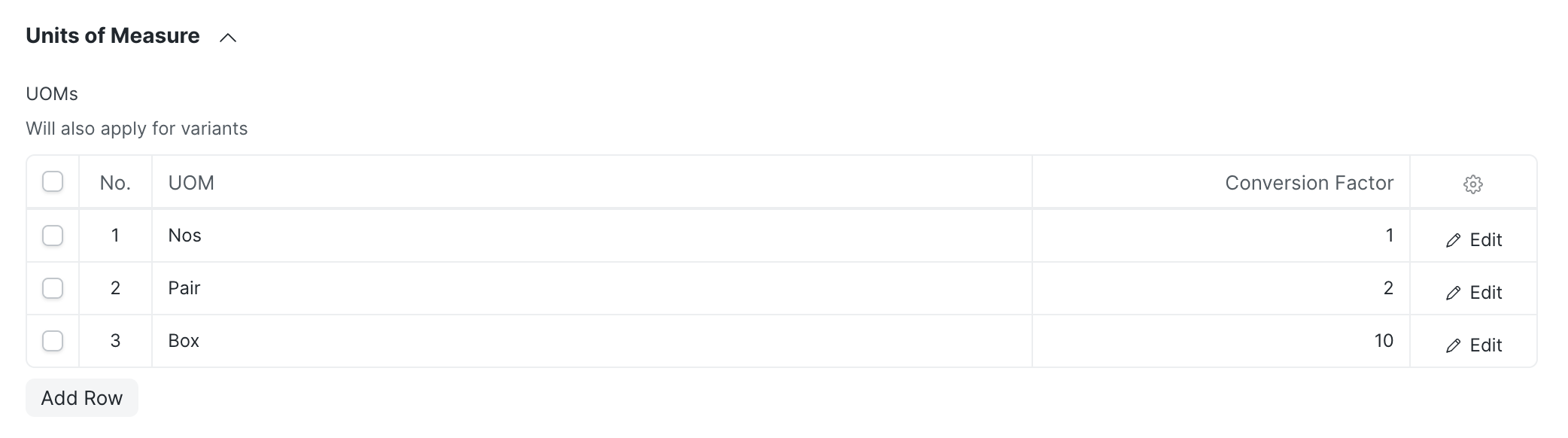

Multiple Units Of Measurement

Don't let systems stop you from measuring materials exactly the way you want! Keep track of different units of measurement for your inventory. Set up conversion factors in the Item master itself and facilitate smooth sales, purchase, and stock transactions. All conversions will be handled by the system.

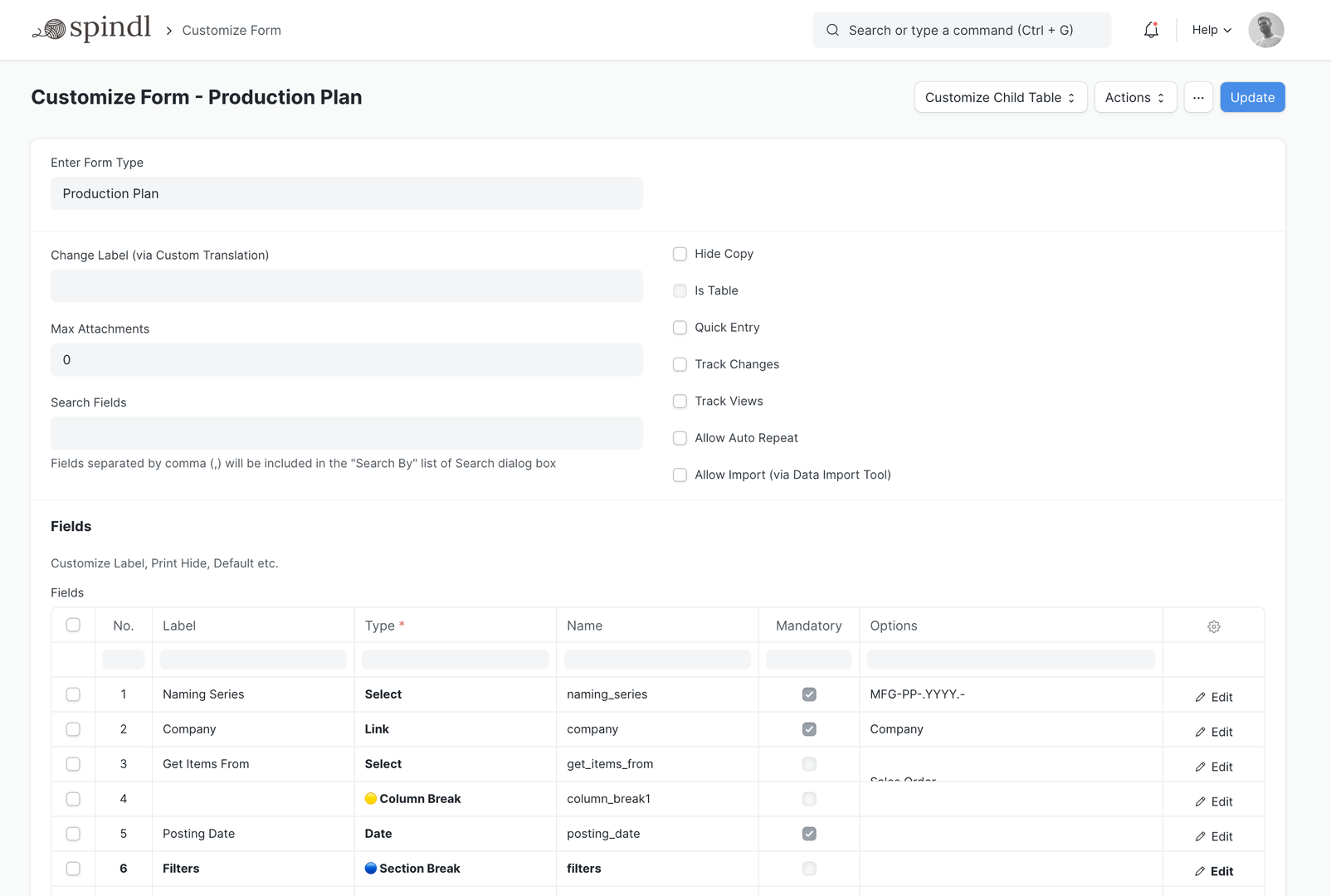

On-The-Fly Customizations

Create your own custom industrial machinery ERP software. Map your most important data by adding custom fields in your forms. Customize form behavior by auto-fetching values, hide fields based on user roles, and create custom print formats — all without a single line of code.

Multilingual Industrial Machinery ERP

ERPNext supports over 100 languages. Localizations build confidence while helping users feel welcome. Can't find your language? Help us translate: https://translate.erpnext.com

Self-Onboarding & Empowerment

All the tools you need to achieve manufacturing excellence are part of the world’s first smart, DIY ERP. Transform your organization with excellent documentation and video tutorials that facilitate a zero-touch, super fast ERP implementation.